Quiet vacuum motors use advanced technology to reduce noise. They are designed to be efficient yet silent.

Understanding how these motors work involves exploring their unique features. Vacuum cleaners are essential in many homes. But, the noise can be irritating. Luckily, quiet vacuum motors offer a solution. These motors use sound-absorbing materials and optimized airflow designs. They minimize the noise without compromising performance.

This makes cleaning more pleasant. Additionally, quiet motors extend the life of the vacuum. By reducing vibrations, they help maintain the machine’s integrity. In this blog post, we will delve into the mechanics of quiet vacuum motors. We’ll explain how they work and the technologies used to reduce noise. Join us to learn how you can enjoy a quieter cleaning experience.

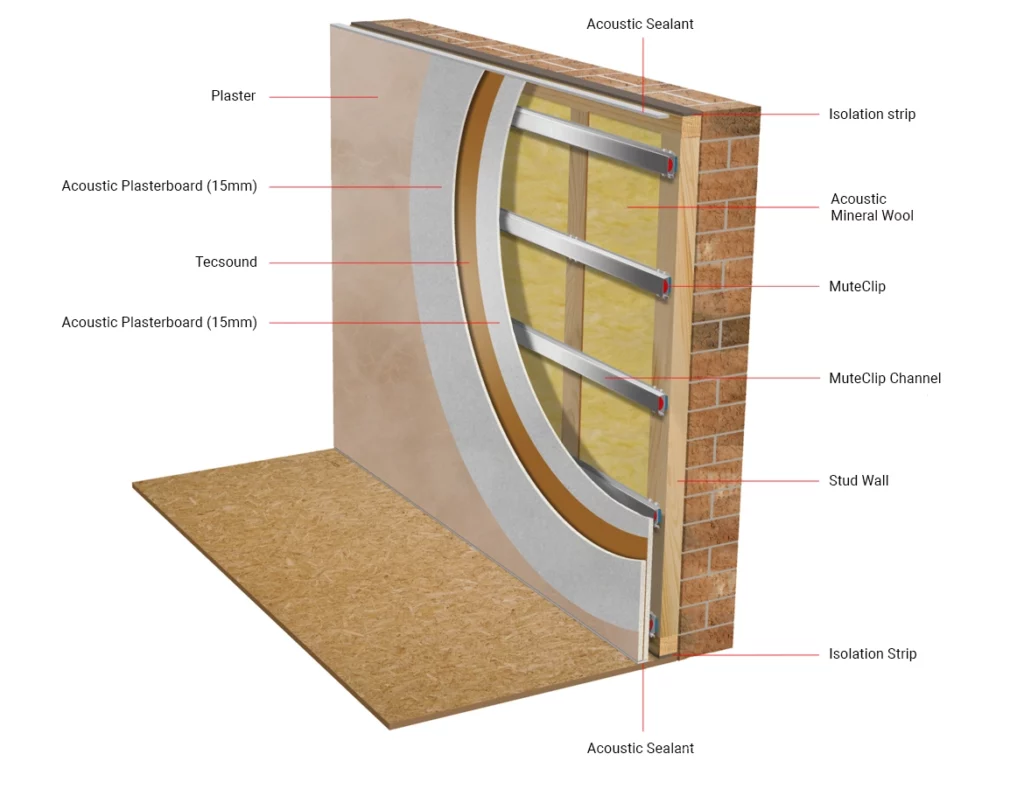

Credit: www.ikoustic.co.uk

Introduction To Quiet Vacuum Motors

Vacuuming is a chore that most of us can’t avoid, but it doesn’t have to be a noisy one. Quiet vacuum motors are a game-changer in the world of home cleaning. These innovations not only make the experience more pleasant but also protect our hearing and reduce overall stress. Let’s dive into the fascinating world of quiet vacuum motors.

The Need For Quiet Motors

No one enjoys the loud roar of a traditional vacuum. It’s disruptive, especially if you live in an apartment or have a baby who needs naps. The need for quiet motors stems from the desire to make household cleaning a less intrusive activity.

Imagine vacuuming while your partner is on a conference call or your kids are doing homework. Quiet motors make this possible. They allow you to maintain a clean home without disturbing everyone around you.

Benefits Of Noise Reduction

Reducing noise isn’t just about comfort. It’s about health too. Constant exposure to loud noises can lead to hearing loss over time. Quiet vacuum motors help mitigate this risk.

Moreover, less noise means less stress. A quieter home environment can significantly improve your mental well-being. You might even find vacuuming a more enjoyable task without the loud, grating sound in the background.

Additionally, pets benefit too. Many animals are terrified of vacuums due to their loud noise. A quieter motor can make the experience less traumatic for your furry friends.

Have you ever thought about how a quieter vacuum could change your cleaning routine? It could make the process smoother and more efficient, allowing you to focus on the task without distractions.

Credit: www.viatomcare.com

Components Of Quiet Vacuum Motors

Understanding the components of quiet vacuum motors can help explain their noise reduction capabilities. These motors use specific designs and materials to operate quietly. We will explore the essential components that contribute to their low noise levels.

Motor Design

Quiet vacuum motors feature specialized designs. These designs focus on reducing vibrations and minimizing noise. Engineers use balanced parts to ensure smooth operation. This reduces the chance of noise from the motor’s internal movement.

The motors often have a lower RPM (revolutions per minute). This lower speed reduces the noise generated. It also helps in maintaining a steady and quiet operation. The design also includes better bearings. These bearings support the motor’s moving parts efficiently. So, less noise is produced during use.

Sound Insulation

Sound insulation plays a crucial role in quiet vacuum motors. Manufacturers use materials that absorb sound. These materials are placed around the motor. They help to block the noise from escaping.

Foam padding is a common choice for insulation. It surrounds the motor and absorbs vibrations. This reduces the noise heard outside the vacuum. Some designs also include insulated motor housings. These housings are made from materials that dampen sound. They ensure the noise stays within the vacuum.

Using these components, quiet vacuum motors achieve a significant reduction in noise. This makes them perfect for homes and offices. The combination of motor design and sound insulation ensures efficient, quiet cleaning.

Technologies In Noise Reduction

Have you ever wondered why some vacuum cleaners are so quiet, while others roar like jet engines? The secret lies in the innovative technologies used to reduce noise. Let’s dive into the details of how acoustic engineering and advanced materials contribute to this quiet revolution.

Acoustic Engineering

Acoustic engineering plays a crucial role in minimizing the noise produced by vacuum motors. Engineers study how sound waves travel and interact within the motor. They design components that can absorb or deflect sound, reducing the overall noise level.

One practical application is the use of sound-absorbing materials. These materials are strategically placed inside the motor housing to dampen vibrations and reduce noise. Think of it as putting a muffler on a car to quiet the engine.

Another technique involves optimizing the shape and design of the motor parts. By tweaking the geometry, engineers can minimize the noise generated during operation. This means your vacuum can clean efficiently without waking the whole house.

Advanced Materials

Advanced materials are another key to noise reduction in vacuum motors. Traditional materials often fail to absorb vibrations effectively. Modern vacuums use cutting-edge materials specifically designed to tackle this issue.

Rubber mounts and gaskets are common examples. These materials cushion the motor, preventing vibrations from spreading and causing noise. Imagine them as the shock absorbers in your car, but for your vacuum.

Additionally, lightweight yet sturdy materials like composites can reduce the weight of the motor. Lighter motors vibrate less, leading to quieter operation. You get a powerful vacuum without the ear-splitting noise.

Have you noticed your vacuum getting quieter over the years? What other features do you think contribute to a silent vacuum experience?

How Quiet Vacuum Motors Operate

Understanding how quiet vacuum motors operate can help you appreciate the technology behind noise reduction in modern vacuums. These innovations make cleaning your home a peaceful experience, without the loud and disruptive noises of older models. Let’s dive into the mechanics behind quiet vacuum motors and explore key aspects like airflow management and vibration control.

Airflow Management

Airflow management plays a crucial role in reducing noise. By optimizing the path air takes through the vacuum, manufacturers can minimize turbulence and noise. Think about how a gentle breeze sounds compared to a stormy wind; smooth airflow is quieter.

Advanced designs include streamlined air ducts and improved filters that help control the flow of air. You may notice your vacuum has multiple layers of filtration. Each layer works to not only clean the air but also reduce the noise produced.

Imagine having a vacuum that doesn’t sound like it’s about to take off. Efficient airflow management makes this possible by ensuring air moves smoothly and quietly through the vacuum.

Vibration Control

Vibration is another major source of noise in vacuum motors. Reducing vibrations can significantly lower the sound output. Engineers use various techniques to control and dampen vibrations.

One common method is using rubber mounts and dampeners around the motor. These materials absorb vibrations and prevent them from causing noise. It’s like having shock absorbers in your car; they make your ride smoother and quieter.

Additionally, balancing the motor components can also help. Properly balanced parts reduce the amount of wobble and vibration, leading to a quieter operation. Consider how balanced a spinning top is compared to a wobbling one; less wobble means less noise.

Have you ever noticed your vacuum doesn’t vibrate as much as older models? That’s vibration control at work, making your cleaning experience quieter and more enjoyable.

By managing airflow and controlling vibrations, modern vacuum motors operate quietly, turning a noisy chore into a more pleasant task. Next time you use your vacuum, think about these innovations that make your home cleaning routine quieter and more efficient. Do you find your vacuum quiet enough, or do you still wish it was less noisy? Share your thoughts and experiences in the comments below!

Comparing Traditional And Quiet Motors

Understanding the difference between traditional and quiet vacuum motors helps in making an informed choice. Traditional motors are known for their loud noise. Quiet motors, on the other hand, have advanced technology that significantly reduces noise levels.

Noise Levels

Traditional vacuum motors often produce loud, disruptive sounds. This can be bothersome, especially in quiet environments. Quiet motors use sound-dampening materials and advanced engineering. These features help in reducing noise output significantly.

Some quiet motors operate at noise levels as low as 60 decibels. This is comparable to a normal conversation. This makes them ideal for homes, offices, and other quiet settings.

Energy Efficiency

Traditional motors usually consume more energy. This can lead to higher electricity bills. Quiet motors are designed to be energy-efficient. They use less power while maintaining strong suction capabilities.

Energy-efficient motors not only save money but also reduce environmental impact. This makes them a more sustainable choice for households and businesses.

Testing And Measuring Noise Levels

When it comes to making vacuum motors quieter, testing and measuring noise levels are crucial steps. Understanding how much noise a vacuum motor produces can help manufacturers design quieter models. Let’s dive into how decibel measurements and laboratory testing play a role in this process.

Decibel Measurement

Decibel measurement is the standard method for gauging noise levels. A decibel (dB) meter is used to measure the sound intensity. Typically, the quieter the motor, the lower the decibel reading.

Have you ever wondered how loud your vacuum is compared to everyday sounds? A standard conversation is about 60 dB, while a noisy vacuum can hit 70-80 dB. A quieter vacuum motor would aim to be closer to that conversational level. This makes a significant difference in your home environment.

Using a decibel meter is straightforward. You simply turn on the vacuum and hold the meter at a specific distance. This is usually standardized for consistency. The meter will give you a reading, which you can then compare to other models.

Laboratory Testing

Laboratory testing offers a controlled environment to measure noise levels accurately. In these labs, vacuums are tested in soundproof rooms. This eliminates background noise and ensures precise readings.

During testing, various aspects of the vacuum are evaluated. These include motor speed, airflow, and the materials used. Each of these factors can impact the overall noise level. By isolating these variables, manufacturers can pinpoint what needs improvement.

Imagine a lab technician working diligently with multiple vacuum models, each with slight variations. This hands-on approach helps identify which design tweaks lead to quieter operation. It’s a meticulous process, but the payoff is a quieter home for you.

Have you ever thought about how your vacuum’s design affects its noise level? Next time you use your vacuum, consider the effort that went into making it quieter. It’s more than just a convenient appliance—it’s a product of detailed testing and precise measurements.

Maintenance For Optimal Performance

Maintaining a quiet vacuum motor is essential for optimal performance. Regular upkeep ensures that the vacuum runs smoothly and remains quiet. This section will guide you through essential maintenance steps. Follow these tips to extend the life of your vacuum motor.

Regular Cleaning

Dust and debris can build up in the vacuum motor. This build-up can cause noise and reduce efficiency. Clean the vacuum motor regularly to prevent this. Use a soft brush to remove dust from the motor. Avoid using water or harsh chemicals. These can damage the motor.

Check the vacuum’s filters. Clean or replace them as needed. Dirty filters can block airflow. This makes the motor work harder and louder. Keeping filters clean helps the motor run quietly.

Component Replacement

Some vacuum parts wear out over time. These include belts, brushes, and bearings. Worn parts can cause noise and reduce performance. Regularly inspect these components. Replace them if they show signs of wear.

Listen for unusual sounds. They can indicate a problem. A high-pitched squeal might mean a belt needs replacing. Grinding noises could point to worn bearings. Address these issues promptly. This prevents further damage and keeps the vacuum quiet.

By following these maintenance steps, you can ensure your vacuum motor stays quiet and efficient. Regular cleaning and timely part replacement are key. Keep your vacuum in top shape for the best performance.

Credit: www.amazon.com

Future Trends In Quiet Motor Technology

The future of quiet vacuum motor technology looks promising. With advancements in design and sustainability, the next generation of vacuum motors will be quieter and more efficient. Let’s explore the key trends shaping this future.

Innovative Designs

Engineers are creating new motor designs to reduce noise. They focus on smoother airflow paths and better insulation. This helps minimize the sound produced during operation.

Some designs use materials that absorb sound. These materials can significantly lower noise levels. Better fan blade designs also play a role. They reduce turbulence, leading to quieter motors.

Sustainability Focus

Sustainability is becoming a key trend in motor technology. Manufacturers are using eco-friendly materials. These materials are not only better for the environment but also help in noise reduction.

Energy-efficient motors produce less heat and noise. Less energy consumption means quieter operation. This makes vacuum motors more sustainable and user-friendly.

Frequently Asked Questions

How Do You Reduce The Noise On A Vacuum Pump?

Reduce vacuum pump noise by using sound enclosures, installing vibration isolators, and ensuring proper maintenance. Use mufflers and silencers.

How Do Silent Vacuums Work?

Silent vacuums use advanced motor technology and soundproofing materials. They reduce noise without compromising cleaning power. Enhanced airflow systems also help in minimizing sound levels.

How Many Db Is A Quiet Vacuum Cleaner?

A quiet vacuum cleaner typically operates at around 60 to 65 decibels. This is comparable to normal conversation noise levels.

How To Reduce The Noise Of A Vacuum Cleaner?

Use a vacuum cleaner with a noise-reducing design. Maintain the vacuum regularly by cleaning filters and brushes. Opt for models with insulated motor compartments. Place a noise-absorbing mat under the vacuum. Choose lower power settings for quieter operation.

Conclusion

Quiet vacuum motors are a marvel of engineering. They reduce noise effectively. This makes cleaning a quieter task. Innovations in motor design play a key role. Soundproofing materials also help a lot. These advancements benefit everyone. Homes stay peaceful during cleaning.

Understanding these motors is fascinating. It shows how technology improves daily life. Now, enjoy a quieter cleaning experience.